Centrifugal Self Priming Mud Pumps (USP Series)

Centrifugal Self Priming Mud Pumps (USP Series)

“U-Neel” Centrifugal Self Priming Pumps are non clog, bare shaft, heavy in weight for sturdiness & better long life. ‘USP’ Pumps are back pull out type construction & fitted with sufficient size of passage to pass solids from the casing. These are most popular & suitable for any kind of dirty water application.

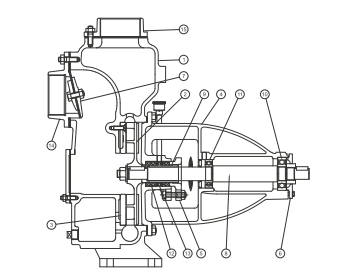

| No. | DESCRIPTION | M.O.C. |

|---|---|---|

| 1 | Pump Casing | C.I.FG260 |

| 2 | Impeller | C.I.FG260 |

| 3 | Wear Plate | C.I.FG260 |

| 4 | Bracket | C.I.FG260 |

| 5 | Gland Cover | C.I.FG260 |

| 6 | Bearing Cover | C.I.FG260 |

| 7 | NRV with Flap | C.I> + Ni. Rubber |

| 8 | Shaft | En8 |

| No. | DESCRIPTION | M.O.C. |

|---|---|---|

| 9 | Sleeve | S.S. 410 |

| 10 | Ball Bearing (DE) | FAG or Eq. |

| 11 | Ball Bearing (NDE) | FAG or Eq. |

| 12 | Gland Packing | Asbestos Graphite |

| 13 | Lantern Ring | PVC |

| 14 | Suction Flange | C.I.FG260 |

| 15 | Deliver Flange | C.I.FG260 |

| Head | upto 60 Mtr |

|---|---|

| Capacity | upto 650 M3/Hr |

| Suction Lift | upto 6 mtr |

| Driver | Motor : 3000/ 1500 RPM Engine :1800 RPM |

| Range | upto 60.0 HP |

| Shaft Sealing | Gland Packed |

| Free Passage | upto 50mm |

Dewatering of Excavation Water, Trenches, Pits, Sewage Pumping, Pumping Watering from Docks, Ports and Vessels, Pumping Petroleum Products, Chemicals, Effluents, Ash Water, Tiles / Marble Slurries, Filter Press etc., Cooling Water for Marine Engines and Solvents.

MATERIAL OF CONSTRUCTION ON REQUEST

Pump Casing : CA15, CF8, CF8M

Impeller : CA15, CF8, CF8M

Wear Plate : CA15, CF8, CF8M

Shaft : AISI 410, AISI 304, AISI 316

Shaft Sleeve :AISI 304, AISI 316

Also Available with on Request

Mechanical Seal Arrangement, Base Frame, Coupling, Coupling Guard, Trolley, Electric Motor

- Back Pull Out design.

- 100% Vacuum Creation for Higher Efficiency.

- No need of External Bearing Lubrication.

- Cost can be Reduced using Monoblock version.

- No need of Foot Valve.

- Vibration Free Operation.

- Easy to Maintenance.