Portable Submersible Pump (UP Series)

Portable-Submersible-Pump (UP)

“U-Neel” High Speed Light Duty Portable Submersible Pump is vertical single casing pump with channel type impeller. Squirrel cage induction motors specially manufactured by “U-Neel” with Class ‘F’ and Class ‘H’ insulation suitable upto 155 C and 180 C for 15 Starts and Stops per hour. “ULS” Pumps are also available with auto coupling arrangement.

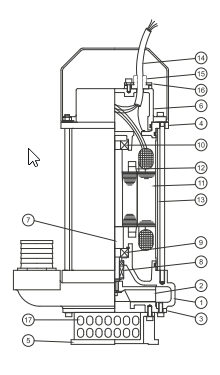

| No. | DESCRIPTION | M.O.C. |

|---|---|---|

| 1 | Pump Casing | C.I.FG260 |

| 2 | Impeller | C.I.FG260 |

| 3 | Wear Plate | C.I.FG260 |

| 4 | Top Cover | C.I.FG260 |

| 5 | Stand | C.I.FG260 |

| 6 | Terminal Box | C.I.FG260 |

| 7 | Shaft | S.S. 410 |

| 8 | Mech, Seal | SiC / SiC |

| No. | DESCRIPTION | M.O.C. |

|---|---|---|

| 9 | Ball Bearing (DE) | SKF or Eq. |

| 10 | Ball Bearing (NDE) | SKF or Eq. |

| 11 | Stator Stamping | Si. Stamping |

| 12 | Rotor Die Cast | Aluminium |

| 13 | Motor Body | S.S. |

| 14 | Cable | PVC Inรน. |

| 15 | Cable Grommet | Ni. Rubber |

| 16 | Cable Clip | S.S. |

| 16 | Strainer | S.S. |

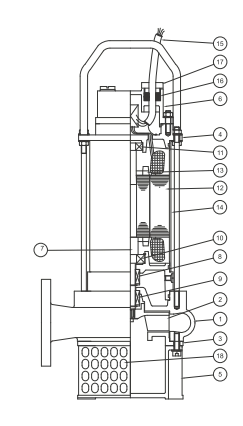

| No. | DESCRIPTION | M.O.C. |

|---|---|---|

| 1 | Pump Casing | C.I.FG260 |

| 2 | Impeller | C.I.FG260 |

| 3 | Wear Plate | C.I.FG260 |

| 4 | Top Cover | C.I.FG260 |

| 5 | Stand | C.I.FG260 |

| 6 | Terminal Box | C.I.FG260 |

| 7 | Shaft | S.S. 410 |

| 8 | Mech. Seal (Upper) | C vs SiC |

| 9 | Mech. Seal (Lower) | SiC / SiC |

| No. | DESCRIPTION | M.O.C. |

|---|---|---|

| 10 | Ball Bearing (DE) | SKF or Eq. |

| 11 | Ball Bearing (NDE) | SKF or Eq. |

| 12 | Stator Stamping | Si. Stamping |

| 13 | Rotor Die Cast | Aluminium |

| 14 | Motor Body | S.S. |

| 15 | Cable | PVC Insu. |

| 16 | Strainer | Ni. Rubber |

| 17 | Cable Gland | Nylon |

| 18 | Strainer | S.S. |

| No. | DESCRIPTION | M.O.C. |

|---|---|---|

| 1 | Pump Casing | C.I.FG260 |

| 2 | Impeller | C.I.FG260 |

| 3 | Wear Plate | C.I.FG260 |

| 4 | Top Cover | C.I.FG260 |

| 5 | Stand | C.I.FG260 |

| 6 | Terminal Box | C.I.FG260 |

| 7 | Shaft | S.S. 410 |

| 8 | Mech. Seal (Upper) | C vs SiC |

| 9 | Mech. Seal (Lower) | SiC / SiC |

| No. | DESCRIPTION | M.O.C. |

|---|---|---|

| 10 | Ball Bearing (DE) | SKF or Eq. |

| 11 | Ball Bearing (NDE) | SKF or Eq. |

| 12 | Stator Stamping | Si. Stamping |

| 13 | Rotor Die Cast | Aluminium |

| 14 | Motor Body | S.S. |

| 15 | Cable | PVC Inรน. |

| 16 | Cable Grommet | Ni. Rubber |

| 17 | Cable Gland | C.I.FG 260 |

| 18 | Strainer | S.S. |

| Head | upto 75 Mtr |

|---|---|

| Capacity | upto 200 M3/Hr |

| Motor | Two Pole Continuous Duty, Squirrel Cage, Submersible type induction motor. |

| Speed (Syn.) | 3000 RPM |

| Connection | DOL (Star Delta optional) |

| Range | 0.75 HP to 30.0 HP |

| Temperature | 45° C (Also available for higher temperature on request) |

| Voltage | 415V, 30. 50 Hz. 230V, 10, 50 Hz. (upto 3.0 HP) 110V, 30, 60 Hz. 110V, 10, 60 Hz |

| Class of Insulation | ‘F’ Class (optional ‘H’ Class available on request) |

| Protection | IP 68 |

- Dewatering of Dirty Water.

- Dewatering of Sandy / Mudiy Water.

- Handling of Storm Watar.

- Suitable for Pits, Dam Sites, River Bed, Construction Sites, Basements, Cable Trenches, Cooling Water Circulation.

- Removal of all sorts of industrial Water, Screened Sewage Water,

MATERIAL OF CONSTRUCTION ON REQUEST

Motor Body : AISI 304, AISI 316, CF8, CF8M

Pump Casing : CF8, CF8M, CF3M

Impeller : CA15, CA40, CF8, CF8M, CF3M

Wear Plate : CA15, CA40, CF8, CF8M, CF3M

Shaft : AISI 420, AISI 431, AISI 304, AISI 316, AISI 316L

Mechanical Seal : SiC / SiC, TC / TC, C / SiC, C/ Cr Steel, C/Ce

Strainer : AISI 304, AISI 316

Cable : HO7RNF, FRLS

Also Available with on Request

Auto Coupling Installation, Cooling Jacket, Auto Level Controller (Float Switch), Thermal Protection, seal Monitoring Arrangement, MCB Starter (for 10)

- Light in Weight.

- Easy Maintenance

- Portable for Easy Handling.

- Bottom Suction & Side Delivery.

- Can be used for Permanent Installation.

- All kind of Discharge Connections Available.