Dewatering Submersible Pump (UD Series)

Dewatering-Submersible-Pump

“U-Neel” Dewatering Pump is compact and sturdy in Design, having light weight and used for continuous duty applications. Cooling jacket and Vertical discharge arrangement is provided to keep motor cool itself by liquid being pumped.

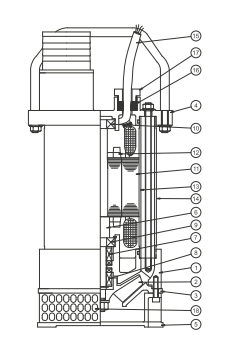

| No. | DESCRIPTION | M.O.C. |

|---|---|---|

| 1 | Casing / Bypess | C.I.FG260 |

| 2 | Impeller | C.I.FG260 |

| 3 | Wear Plate | C.I.FG260 |

| 4 | Delivery Out Let | C.I.FG260 |

| 5 | Stand | C.I.FG260 |

| 6 | Shaft | S.S. 410 |

| 7 | Mech. Seal (Upper) | TC VS TC |

| 8 | Mech. Seal (Lower) | TC VS TC |

| 9 | Ball Bearing (DE) | SAF or Eq |

| No. | DESCRIPTION | M.O.C. |

|---|---|---|

| 10 | Ball Bearing (NDE) | SKF or Eq. |

| 11 | Stator Stamping | Si. Stamping |

| 12 | Rotor Die Cast | Aluminium |

| 13 | Motor Body | S.S. |

| 14 | Outer Casing/jacket | S.S. |

| 15 | Cable | PVC Inรน. |

| 16 | Cable Grommet | Ni. Rubber |

| 17 | Cable Gland | Nylon |

| 18 | Strainer | S.S. |

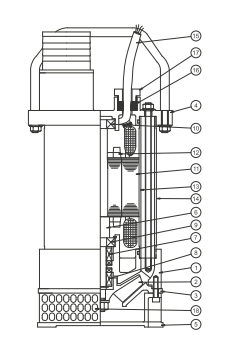

| No. | DESCRIPTION | M.O.C. |

|---|---|---|

| 1 | Casing / Bypass | C.I.FG260 |

| 2 | Impeller | C.I.FG260 |

| 3 | Wear Plate | C.I.FG260 |

| 4 | Delivery Out Let | C.I.FG260 |

| 5 | Stand | C.I.FG260 |

| 6 | Terminal Box | C.I.FG260 |

| 7 | Shaft | S.S. 410 |

| 8 | Mech. Seal (Upper) | TC vs TC |

| 9 | Mech. Seal (Lower) | TC vs TC |

| No. | DESCRIPTION | M.O.C. |

|---|---|---|

| 10 | Ball Bearing (DE) | SKF or Eq. |

| 11 | Ball Bearing (NDE) | SKF or Eq. |

| 12 | Stator Stamping | Si. Stamping |

| 13 | Rotor Die Cast | Aluminium |

| 14 | Motor Body | S.S. |

| 15 | Outer Casing/Jacket | S.S. |

| 16 | Cable | PVC Inรน. |

| 17 | Cable Grommet | Ni. Rubber |

| 18 | Cable Gland | Nylon |

| 19 | Strainer | S.S. |

| No. | DESCRIPTION | M.O.C. |

|---|---|---|

| 1 | Casing / Bypess | C.I.FG260 |

| 2 | Impeller | C.I.FG260 |

| 3 | Wear Plate | C.I.FG260 |

| 4 | Delivery Out Let | C.I.FG260 |

| 5 | Stand | C.I.FG260 |

| 6 | Terminal Box | C.I.FG260 |

| 7 | Shaft | S.S. 410 |

| 8 | Mech. Seal (Upper) | C vs SIC |

| 9 | Mech. Seal (Lower) | SIC vS SIC |

| 10 | Ball Bearing (DE) | SKF or Eq. |

| No. | DESCRIPTION | M.O.C. |

|---|---|---|

| 11 | Ball Bearing (NDE) | SKF or Eq. |

| 12 | Stator Stamping | Si. Stamping |

| 13 | Rotor Die Cast | Aluminium |

| 14 | Motor Body | M.S. |

| 15 | Outer Casing/jacket | M.S. |

| 16 | Cable | PVC Inรน. |

| 17 | Cable Grommet | Ni. Rubber |

| 18 | Cable Gland | C.I.FG260 |

| 19 | Strainer | S.S. |

| Head | upto 75 Mtr |

|---|---|

| Capacity | upto 600 M3/Hr |

| Motor | Two / Four Pole Continuous Duty, Squirrel Cage, Submersible type Induction Motor |

| Speed (Syn.) | 3000 / 1500 RPM |

| Connection | DOL (Star Delta optional) |

| Range | 0.75 HP to 70.0 HP |

| Temperature | 45° C (Also available for higher temperature on request) |

| Voltage | 415V, 30. 50 Hz 230V, 10, 50 Hz (upto 3.0 HP) 110V, 30, 60 Hz 110V, 10, 60 Hz |

| Class of Insulation | ‘F’ Class (optional ‘H’ Class available on request) |

| Protection | IP 68 |

| Concentration | 50000 ppm |

| Free Passage | upto 25mm |

- Dewatering of Dirty Water.

- Dewatering of Sandy / Muddy Water.

- Handling of Storm Water.

- Suitable for Pits, Dam Sites, River Bed. Construction Sites,

Basements,CableTrenchess, Cooling Water Circulation.

MATERIAL OF CONSTRUCTION ON REQUEST

Motor Body : AISI 304, AISI 316

Outer Casing : AISI 304, AISI 316

(Cooling Jacket)

Pump Casing : CF8, CF8M, CF3M, Aluminium Alloy,

Impeller : CA15, CA40, CF8, CF8M, CF3M

Wear Plate : CA15, CA40, CF8, CF8M, CF3M

Shaft : ASI 420, AlS 431, AISI 304, AISI 316, AISI 316L

Mechanical Seal : SiC / SiC, TC / TC, C / SIC, C / Cr Steel, C/Ce

Strainer : AISI 304, AISI 316

Cable : HO7RNF, FRLS

Also Available with on Request

Auto Level Controller (Float Switch), Thermal Protection,MCB Starter (for 10)

- Light in Weight.

- Works in Partially Submergence.

- Portable for Easy Handling.

- Can handle upto Minimized Water Level.

- Prevents Motor Heating Through Jacket.

- Bottom Suction & Top Centre Lined Delivery.

- Easy Maintenance.

- Double Mechanical Seals with Hard Face Combination.